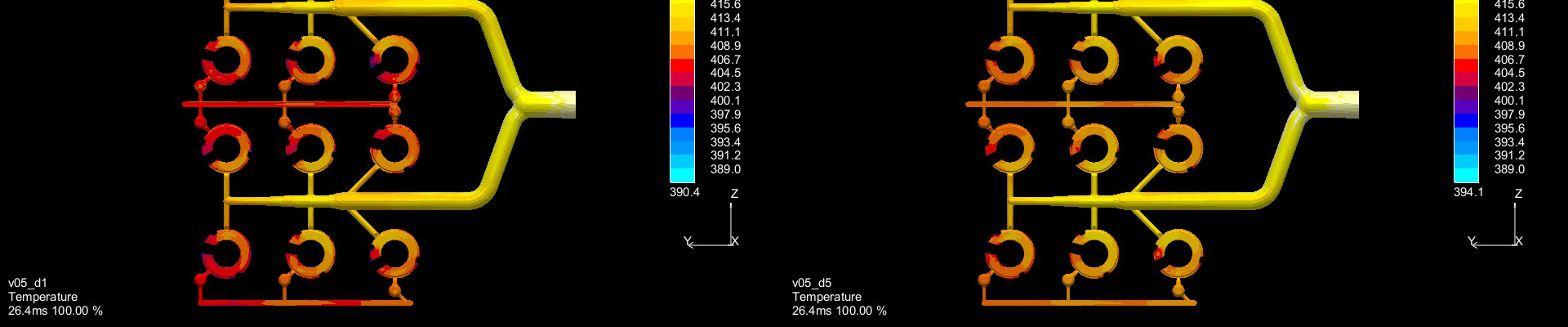

Flow simulation is a powerful tool for predicting casting quality during the early stages of mold development, before production even begins. By analyzing mold filling, solidification, and thermal behavior, engineers can identify potential defects, optimize gating and venting systems, and improve overall casting performance. Early simulation helps reduce costly design changes, shorten development cycles, and enhance first-shot success rates. At Cast Products, Inc., we utilize advanced simulation software, including MAGMASOFT®, to support data-driven decisions and improve collaboration between design and production teams.

Proudly Made in the U.S.A.

Proudly Made in the U.S.A.