Zinc Die Casting for Electronics

Zinc die castings are widely used in the electronics industry due to their unique properties such as strength, durability, and thermal conductivity. The precision of the casting process also allows casting complex shapes with tight tolerances, which is important in the electronics industry where precision and accuracy are critical. Precision Zinc die casting for electronics is one of the many services offered by Cast Products.

Main Application of Zinc Die Casting for Electronics

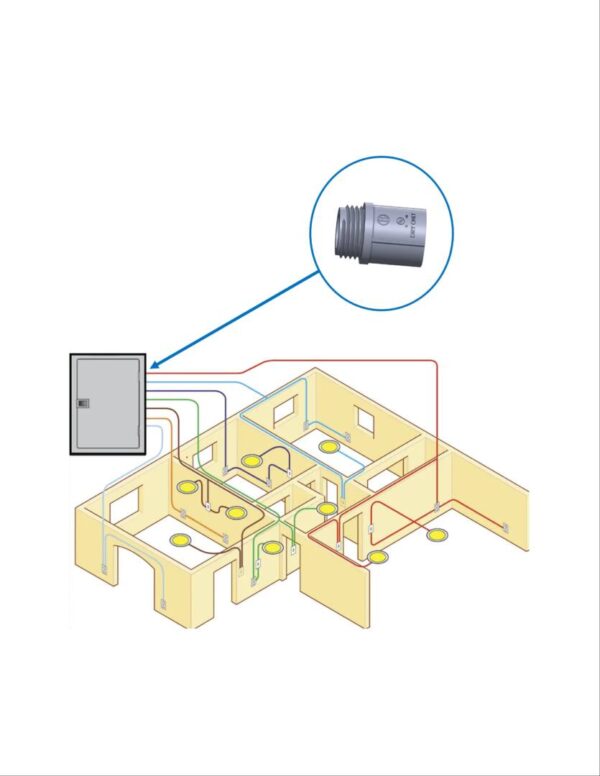

One of the main applications of zinc die castings for the electronics industry is in the production of electronic enclosures. These enclosures are designed to protect electronic components from the environment and to provide a secure mounting point for circuit boards and other components. Zinc die castings are ideal for electronics applications because they are resistant to corrosion. In applications where the housing may be exposed to the environment, there are several options for corrosion protection that work well on Zinc castings.

In addition to their strength and durability, zinc die castings are also highly resistant to electromagnetic interference (EMI) and radio frequency interference (RFI). This helps improve the EMI/RFI shielding for the electronic. This “shielding” is the method of limiting external interference from electromagnetic fields and signals. These signals may disrupt the functionality of your electronic devices. By using components with increased RFI/EMI shielding properties, like Zinc die cast parts, it helps prevent electronic malfunction by blocking electromagnetic waves from interfering with circuits. This makes Zinc components an ideal choice for electronic products that need to be shielded from interference to function properly. Creating protected electronics is much easier with quality Zinc die casting.

Zinc Connectors and Electronics Housing

Zinc die castings are also widely used in the production of connectors and housings for electronic components. These components require high precision to function properly, and zinc die castings can provide the necessary tolerances. Zinc die casting components are also able to withstand the high levels of stress and strain that are associated with these types of electronic components.

Producing Heat Sinks With Zinc Die Casting

Another application of Zinc die castings in the electronics industry is in the production of heat sinks. Heat sinks are designed to dissipate heat generated by electronic components, and Zinc die castings can provide the necessary thermal conductivity to effectively dissipate heat. Many of these Zinc alloy properties are near or superior to aluminum alloys. Zinc die castings can also be designed to have complex geometries that maximize surface area and optimize heat dissipation. If you need to create top quality heat sinks then choose Zinc die casting.

Producing Electronic Tools and Equipment with Zinc Alloys

Zinc alloys are also used in the production of various types of electronic tools and equipment such as handheld devices, laptop computers, and audio equipment. These electronic products require a high level of precision, as well as strength and durability to withstand the demands of everyday use. Zinc die castings can provide the necessary properties required for these electronics products, making them an ideal choice for the technology industry.

Using the Zinc Die Cast Process for Electronic switches and relays

Zinc die castings are also used in the production of various types of electronic components such as switches and relays. These components require high precision and accuracy to function properly, and zinc die castings can provide the necessary tolerances and surface finishes. Zinc die castings are also able to withstand the high levels of stress and strain that are associated with these types of components.

Zinc Die Casting for Electronic Instrumentation

Zinc die castings are also used in the production of various types of electronic instrumentation such as test equipment and measuring devices. Zinc die castings can provide the necessary tolerances and surface finishes. Zinc die castings are also able to withstand the high levels of stress and strain that are associated with these types of products.

How Zinc Die Casting is Used for LED Lighting

Another application of zinc die castings in the electronics industry is in the production of LED lighting components. LED lighting is becoming increasingly popular due to its energy efficiency and long lifespan, and zinc die castings are an ideal choice for producing the housings and heat sinks required for LED lighting products. Zinc die castings can provide the necessary thermal conductivity to effectively dissipate heat, as well as the precision and accuracy required to produce complex geometries that optimize light output. If you are manufacturing lighting that uses LED, Zinc die casting is the right choice for you.

Finally, zinc die castings are also used in the production of various types of electronic consumer products such as cameras, gaming consoles, and home entertainment systems. These products require strength and durability to withstand the demands of everyday use. Zinc die castings can provide the necessary properties required for these products, making them an ideal choice for the electronics industry.

Choose Cast Products for Zinc Die Casting for Electronics

As you can see Zinc die casting is used for a variety of electronic components and is critical to the electronics industry. To create high quality, reliable electronics that are protected, then you need precision Zinc die casting. We’d recommend partnering with a US based company to get the best quality, and most reliable production.

If you have an Electronics application, please contact us at Cast Products via the Get Quote or Ask An Expert buttons on our website.

Proudly Made in the U.S.A.

Proudly Made in the U.S.A.