Industrial ZINC DIE CASTING BENEFITS

One of the main applications of zinc die castings in industrial products is in the production of mechanical components such as gears, cams, and bearings. These components require a high level of precision to function properly, and zinc die castings can provide the necessary tolerances to meet these requirements. Zinc die castings are also able to withstand the high levels of stress and strain that are associated with these types of components. Physical property data is available on our website at Zinc Die Casting Industry Resources – Cast Products, Inc.

Zinc die castings are also widely used in the production of various types of housings and enclosures for industrial equipment such as motors, generators, and pumps. These housings and enclosures are designed to protect the equipment from the environment and to provide a secure mounting point for internal components. Zinc die castings are ideal for this application because they are highly resistant to corrosion and can be designed to have excellent surface finishes.

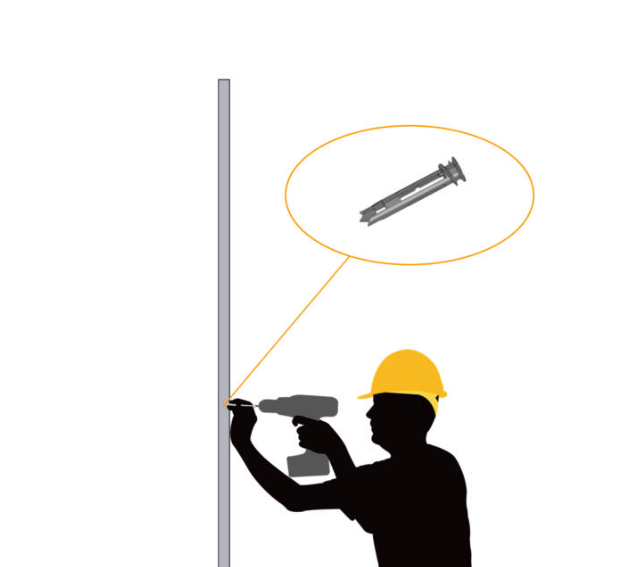

Zinc die castings are also used in the production of various types of hand tools and power tools like wrenches, pliers, and drills. These tools require a high level of strength and durability to withstand the demands of everyday use. Zinc die castings can provide the necessary properties required for these tools, making them an ideal choice for the industrial sector.

Another application of zinc die castings in industrial products is in the production of conveyor components such as rollers, brackets, and guides. These components require high precision and accuracy to function properly, and zinc die castings can provide the tolerances necessary. Zinc die castings are also able to withstand the high levels of stress and strain that are associated with these types of components.

We also see zinc die castings used in the production of various types of valves and fittings for industrial applications such as plumbing and HVAC systems. These components require tight dimensional tolerancing, as well as strength and durability to withstand the demands of everyday use.

Zinc die castings can provide the necessary properties required for these components, making them an ideal choice for the industrial sector. Zamak alloys are also used in the production of various types of pumps and compressors for industrial applications. These components normally house other parts to produce an assembly.

Dimensional accuracy is critical for final assembly, and the ability to cast net shape reduces the number of secondaries required. Also, Zinc die castings are also able to withstand the high levels of stress and strain that are associated with mechanical assemblies in these applications.

In addition to their strength and durability, zinc die castings are also highly resistant to corrosion and chemical damage when finished with the proper level of paint or plating. Finish flexibility makes zinc components an ideal choice for industrial products that are exposed to harsh environments or corrosive chemicals. Zinc die castings can be designed to have excellent surface finishes that resist corrosion and can also be coated with additional protective layers if necessary.

Proudly Made in the U.S.A.

Proudly Made in the U.S.A.